Inspection, measurement and documentation

Quality that convinces

ninka align their quality standard with a zero fault policy and the industry-specific requirements of our customers. The following tools and methods are established at ninka and applied regularly:

-

CAQ inspection system from incoming goods to the finished product

-

Quality pre-planning for determining and fulfilling in-process quality criteria

-

Planning and design of product-specific testing and measurement systems

-

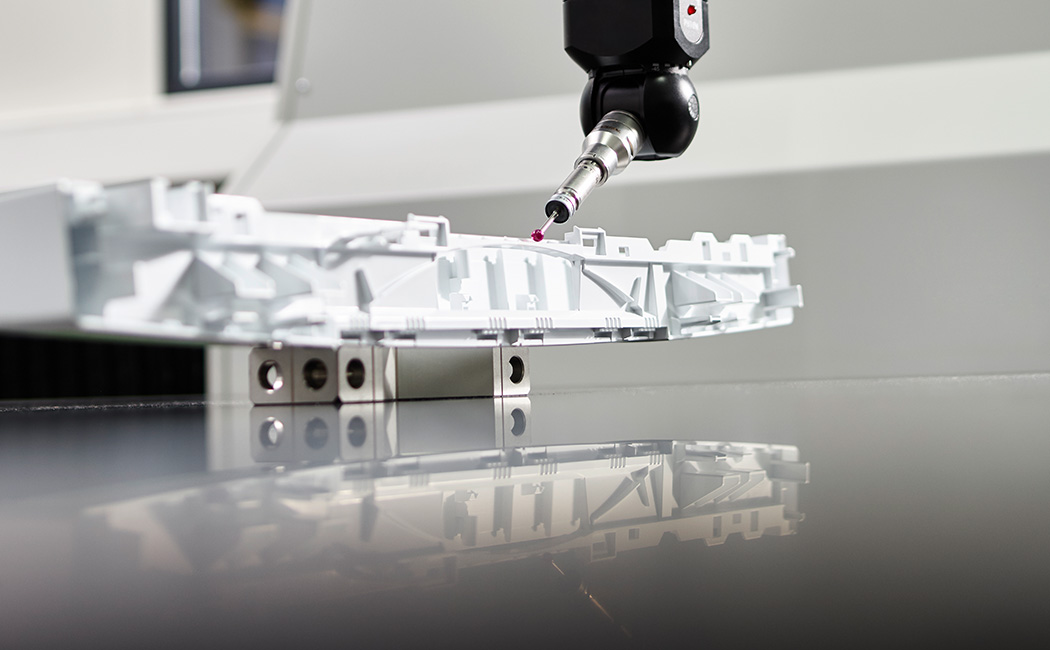

Tactile 3D measurement technology in the measurement range (x-y-z) 1,000 mm - 2,000 mm - 800 mm

-

Optical measuring methods such as CT, X-ray and scanning in cooperation with

external partners -

Documentation of production and test data using a manufacturing execution system (MES)

-

Camera-supported quality inspection